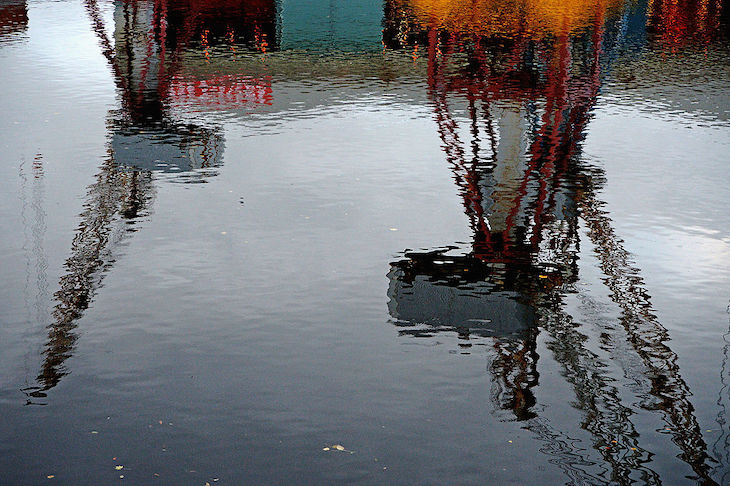

‘Pigeons, beaten to a fine lead by hunger, flickered amongst the rusted girders of the railway bridge… rubble was being trucked from busted gable ends, and demolishers worked in a fume of dust and smoke. You would’ve thought that the Ruskies had finally lobbed over one of their big megaton jobs.’ Jeff Torrington’s brutal poetry in Swing Hammer Swing! captured the death of Glasgow shipbuilding, when the Clyde’s cranes fell silent and the yards were written off as relics.

Half a century on, the noise is back. The clang of cranes, the hiss of welders, the shuffle of apprentices in overalls: the Clyde is stirring again. Shipbuilding jobs in Scotland have risen from 6,000 to more than 7,200 in the past decade. It is not the mass employment of the 1950s and 60s, when tens of thousands crowded the slips, but it is real, durable, investment-driven work. BAE’s new Janet Harvey Hall at Govan – a cavernous cathedral of steel, large enough to construct two warships side by side – symbolises a return of ambition.

The shipbuilding story is not about nostalgia. It is about the rediscovery of industrial strategy as a tool for national renewal

The turning point was the 2017 National Shipbuilding Strategy. Its promise was simple but transformative: a steady pipeline of modern, export-friendly ships for the Royal Navy, giving British yards the confidence to invest in skills and technology. No more boom and bust, no more idle cranes. The results are visible. Rosyth hums with the Type 31 frigate programme; Glasgow is pioneering digital design and advanced welding; Babcock is expanding its apprenticeships.

The export story is equally striking. The Type 31 is being built on time and already sold abroad to Indonesia and Poland. More dramatically, the Type 26 frigates have become the most valuable naval export programme in the world: Australia, Canada and Norway together account for an extraordinary £66–74billion of orders, dwarfing rival frigate or submarine projects. Add Britain’s share of the Aukus submarine pact, expected to generate up to £20billion in exports to Australia over the next quarter-century, and a new reality emerges. After decades of decline, Britain is not just building ships again – it is back as probably the world’s leading naval exporter in programme value.

Nor is the revival confined to warships. The Advanced Propulsion Centre, launched in 2013 with £1billion of joint government–industry funding, has backed more than 300 projects, from Wrightbus hydrogen fleets to Jaguar Land Rover’s electric drivetrains. Its purpose is simple but transformative: to make Britain a leader in low-carbon transport while anchoring supply chains and skills at home. The results include £1.65billion of investment secured and the safeguarding or creation of 59,000 jobs.

There are other successes. The UK Battery Industrialisation Centre near Coventry provides state-of-the-art kit to accelerate electrification. The Catapult network, launched in 2011, channels £1.6billion into bridging research and industry, from offshore renewables to advanced manufacturing. Each mirrors the shipyards’ winning formula: patient capital, ecosystem investment and a clear national purpose.

Defence has another grand project in play: the Global Combat Air Programme (GCAP) with Italy and Japan, also known as the Tempest. Set in motion by the Combat Air Strategy of 2018, it committed nearly £2billion over a decade to preserve sovereign design and manufacturing. The stakes are immense: industry projections suggest the programme could sustain 21,000 jobs annually and deliver £26billion in value by 2050. GCAP is not just about producing a sixth-generation fighter by 2035 – it is about ensuring Britain remains able to design and build at the cutting edge of aerospace. With the Franco-German rival reportedly hitting the buffers, the British-led programme could prove even more successful.

But it would be naïve to think industrial strategy always delivers. Britain has a long record of plans that faltered. Theresa May’s 2017 Industrial Strategy was abandoned within two years, its initiatives in skills and regional growth left to wither. The much-trumpeted Green Homes Grant of 2020, billed as a £2billion boost to create 100,000 jobs in retrofitting, collapsed within six months amid administrative chaos. These failures underline that strategy alone is not enough: consistency, competence and political will are as vital as capital.

For years, critics argued that government’s reluctance to back small modular nuclear reactors was another such failure, even though Rolls-Royce appeared to have the strongest SMR product on the market. That stance has now shifted. With a dedicated SMR strategy in place, Whitehall is finally aligning behind the company – but Rolls-Royce had already taken the lead. Its SMR programme shows how industrial strategy can begin in the boardroom as much as in government. Each compact, factory-built unit promises not only clean power, but an economic prize of £52billion to the UK, 40,000 jobs by 2050 and a supply chain that is 80 per cent British. The export potential is vast: deals secured in the Czech Republic, serious prospects elsewhere in Europe, and the chance of as much as £250 billion in overseas sales. Here is British engineering not waiting for Whitehall’s blessing, but forcing it to catch up.

The shipbuilding story is not about nostalgia. It is about the rediscovery of industrial strategy as a tool for national renewal. Whether in shipyards, aerospace hangars or nuclear workshops, the formula is the same: long-term planning, skilled people, predictable pipelines and the confidence to invest. This is not about picking winners for old times’ sake. It is about strategic stewardship in a world where resilience itself is a measure of power.

Britain, so long suspicious of industrial policy, has stumbled into an unlikely success story. The slipways of the Clyde, the new complex at Govan, the apprentices learning their trades: these are not ghosts of the past. They are evidence that decline is not inevitable. With strategy, Britain can build again. Rivet by rivet, reactor by reactor, fuselage by fuselage, a new age of national industrial success is taking shape.

Comments