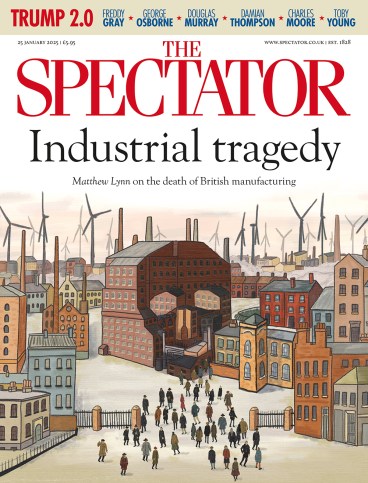

The ceramics industry of Stoke-on-Trent is one of the great survivors of the Victorian era. At its height, some 70,000 people were employed by the likes of Wedgwood and Spode to work in the potteries. Despite the Clean Air Act of 1956 – which banned coal-fired kilns – the deindustrialisation of the 1980s and the struggle to compete against the rise of cheaply made Chinese goods, the industry lives on and still employs around 7,000 people, manufacturing everything from teapots to tiles for the London Underground.

In 2022, some companies saw their six-month energy bills rise tenfold

Stoke can at times seem like it’s living in the ruins of its past – but while the ceramics sector is no longer a large industry, it is still hugely important to the city. Once again, though, it is under threat: this time from high energy prices and rising costs.

Moorland Pottery is one of the firms affected. It is among Stoke’s smaller ceramic businesses, but also a success story. It is based in an old pottery built in 1888, with the blackened bricks of one of Stoke’s bottle kilns overlooking its cobbled courtyard. At one point 4,000 of these kilns were dotted around the city. Now there are just 47. Founded 38 years ago, Moorland mainly manufactures mugs with various local designs. The whole process is done in-house. Despite only having six employees, the company makes around 40,000 mugs a year, all to order.

Most of the production takes place on two floors of the factory. Upstairs, next to the unused chambers of the old bottle kiln, the clay is mixed and pumped next door to be cast into moulds. Downstairs is for dipping, firing, glazing, decorating and packing. The business uses two electric kilns: one for enamelling, which fires once per day in the evening, and a bigger gloss kiln, which fires once or twice a week. When I visit on a cold Monday morning, the room is still warm from the kiln being fired the night before.

It is the high energy usage of the kilns which is a big part of the problem for the industry. Jonathan Plant, Moorland’s co-founder, tells me that its energy bills have gone up from around £900 to up to £2,500 a month. In a business with tight margins, that makes a huge difference. ‘The whole energy system is just broken,’ he says.

It’s not just small potteries affected by energy prices. In 2022, some companies saw their six-month energy bills rise tenfold. That year one of the city’s major firms, Wade Ceramics, went into administration. Last year, Portmeirion announced 35 job cuts and losses of £2 million in the first half of the year.

Even businesses which have been shielded from high energy prices have felt the pinch. A spokesman from Emma Bridgewater tells me the company was fortunate enough to fix its energy prices a few years ago, and so it hasn’t been as affected by recent soaring prices. Still, last year the firm was forced to cut 36 jobs because of rising costs and lower sales.

‘It’s not just the cost of the energy, it’s also the cost of all our suppliers… Every single thing has gone up,’ Plant says. ‘You get to the point where you can perhaps put 50p on to mitigate that increase. But you soon get to the top when your product becomes unaffordable.’ There has also been a ‘real steady decline’ in retail in the past few years.

The last Budget won’t help matters, especially the government’s decision to raise national insurance contributions for employers. This again will affect businesses with narrow margins, particularly in manufacturing.

In many ways, the timing couldn’t be worse. This year is the centenary of Stoke-on-Trent receiving city status, and the legacy of the pottery industry will be central to the celebrations. The way things are going, though, it seems unlikely that there will be much of a ceramics industry left by the time of the next anniversary.

Matthew Lynn, trade unionist Paul Nowak, and The Spectator’s Lara Prendergast and William Moore unpack Britain’s industrial problems further on the latest Edition podcast:

Comments